Date: 22nd July

2007

Location: Workshop and pool

Conditions: Cool and sunny.

Rockets:

(click the name for rocket details)

|

Name |

Capacity |

Notes |

|

Acceleron IIIb |

24

L |

A newly rebuilt rocket after

Acceleron III exploded on the launch

pad during a full system test. |

|

Tachyon II |

2.5

L |

An upgraded sustainer that

provides better support during

liftoff. |

Team Members at

Event:

GK and PK

After a couple of weeks work, we have

rebuilt the Acceleron III

booster now designated Acceleron IIIb. During the rebuild we have also

made the following upgrades to it:

- All the neck to base couplings had

the lids replaced with the long threaded

lids. They now also have reinforcing

rings around them to stop them deforming

when they are tightened.

- All couplings have new seals.

- The inter bottle separating rings

have been replaced with continuous ones.

These are made from 2.25L bottles.

- The capacity of the booster was

decreased 0.75L because we used 2 L

bottles for all booster segments.

Acceleron III had three 2.25L bottles in

the stack.

- The nozzle lids have been

reinforced.

- The sustainer now is better

supported to withstand take-off forces.

- The sustainer fins have been

replaced by a different arrangement to

allow the sustainer to be supported by

the booster.

- The coupling holes in the bottles

have been heat treated to reduce the

risk of hairline cracks developing under

pressure.

- The flight software has been

upgraded to better reflect the state of

the computer.

Flight computer V1.4 details are now

available.

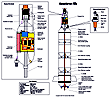

The rocket

gallery now includes a diagram with

descriptions of the

Acceleron IIIb booster components.

Burst Tests

We performed a number of burst tests to

get a sense of how these particular 2L bottles

perform. The results of these tests can be

found in the

burst test section results.

This time we tested the bottles under

water so that they wouldn't produce such a

big bang and any flying debris would also be

contained. The bottles being filled with

water and being submerged simply make a

relatively low thud and some bubbles. The

outside pressure of the water is less that

0.5psi so it really does not effect the

burst pressure.

We also tested two bottles coupled

together using the same coupling that

Acceleron III uses. One of the bottles burst

at around 165psi and it looks like the crack

propagated from the bottle outside diameter

to the coupling hole. This then fanned out

in multiple directions from the hole. One

thing it did teach us about the coupling is

that it can hold up the burst pressure of

the bottles.

A while back while

testing

reinforcing of bottles the Gardena

nozzle attachment kept flying off and so for

these tests we made a permanent connection

to the lid. The lid was also secured with a

pipe clamp.

The upshot of the tests is that we will

be pressurising only to 110psi instead of

the 120psi as originally planned. Although

120psi is still feasible, the first flights

will be at the lower pressure. Once we have

a few good flights under our belt, we may

increase the pressure a little, and later we

will have a go at reinforcing the bottles.

Parachute

We have also finished making the

parachute. Originally we wanted to make the

parachute from a flat hexagonal sheet of

Ripstop nylon. We even bought the material

and cut it out, but decided to go with the

material from one of those large golf

umbrellas instead. The shape is more correct

for a parachute than a flat sheet, and it

has already been properly edged. I actually

found it on the way home on the side of the

road still attached to a destroyed umbrella,

after the last set of Sydney storms. The

parachute is 1500mm in diameter and weighs

120

grams.

We sewed reinforcing ribbon to the shroud

line attachment points and used some heat

shrink tubing over the knots to stop them

from unravelling. There are two main

parachute lines for redundancy, should one

of them snap during a deploy, the other

should still bring the booster to a gentler

landing, although at a less optimal

attitude. The booster is designed to fall

sideways under the parachute to increase the

drag of the rocket on the way down.

Miscellaneous

- I called the

local manufacturer

of the 2L bottles to

see if I could by a small batch but they

said they do not deal with orders smaller

than 100,000! But they suggested I call the

local distributor. They said they can do

smaller lots, but only by the palette which

contained just over 500 bottles at 38c each.

That was still a little too much so we are

just buying them off the shelf in a

supermarket. Aldi sells them for 99c each

with lemonade. Franklins sells them for

$1.09.

- We have also tested mounting the hand

held DV camera to a

wooden boom to steady it when filming

zoomed in at a distance. Since a tripod

makes it very difficult to track a rocket

quickly, the shoulder mounted boom seemed to do a reasonable

job at reducing the shake. We will make

slight adjustments to it and we will use it

to film the sustainer at a distance.

- The sustainer's removable fin assembly

has been removed (now being used on a new

rocket under construction) and was

replaced by a new skirt that helps support

the sustainer during takeoff. The fins are

permanently attached to the skirt. For

strength the skirt is glued to the

sustainer body with PL premium.

- There are still a few minor things to

finish and we should be able to do all the tests

again very soon. And hopefully fly as soon

as possible after that.

|