Introduction

This is the build log of our rocket

project called "Inverter". The log is in chronological order so to

see the most recent post you need to

Jump To The Bottom.

You may need to refresh this page to see any

latest updates.

Design

|

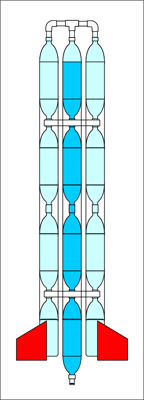

The Inverter rocket is based on a central

pressure chamber that mostly contains water

and two side mounted air-only pressure

chambers. They are joined together at the

top using an air manifold made from PVC

tubing. The rocket's name comes from the fact that

the flow of air is inverted inside the

rocket.

This approach allows one to build a large

capacity single nozzle rocket out of regular

bottles without the rocket being too long.

This concept has been used over the years by

water rocketeers. Here are some

examples:

Because the rocket only uses a single

nozzle it simplifies the launcher design and

allows us to use our existing one without

modification. The flat rocket is also easy

to attach to the guide rail.

We chose to use 2 air chambers in order

to reduce the overall drag and since water

rockets are also usually filled to 1/3 water

it meant we could fill the central segment

almost completely with water. Having a

longer central segment also meant that water

could be distributed vertically in the

rocket and hence helping to increase the

stability.

|

Build Log

12th December 2012

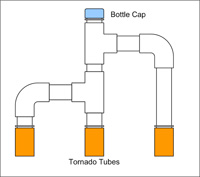

- Designing the manifold. Since this was

going to be an important part of the rocket

we decided to start with the manifold. We wanted to have an opening on the top

of the central segment so that we could fill

it with water once it was on the pad. It

would be difficult to turn it upside

down to fill it and not have the water flow

into the air-only segments. The other

alternative would have be to fill the

rocket through the nozzle, but our launcher

isn't set up for that, so we chose to simply

add an opening at the top of the rocket.

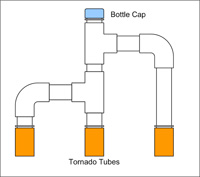

We wanted to use the tornado couplings so

that we could easily assemble or replace the

segments as needed, and use our standard

components. We added enough spacing between

the manifold pipes to allow us to use wider

segments in the future.

The manifold looks funny the way it is

because we wanted to have a 4 way connection

above the central segment, but they don't

sell them at the local hardware shop. They

only sell T-connectors. When I asked the

sales guy, he said "This is the plumbing

section, this isn't the furniture section."

A little bewildered I said "OK" So either

there is something about plumbing that only

needs T-connectors, or somewhere out there

there is furniture made from PVC piping.

Checking on-line, I can see there are X

pieces available for PVC pipes... hmmmm.

Based on the layout below we bought the

necessary components at the local hardware

store.

13th

December 2012 - We cut out

all of the pieces and assembled them with

the tornado couplings, and weighed

everything... 235 grams was way too much for

just the manifold! It was time to re-think

the overall design to reduce the weight so

we decided to change the design to just a T

and 2 elbows. We also decided against using

the tornado tubes and would attach the

captive caps to the PVC tubes. Sealing would

be achieved by soft rubber washers under the

caps. We were going to loose the ability to

fill the rocket from the top, but would

still be able to if the whole manifold was

removed.

Original manifold plan turned

out to be too heavy,

but did have access to the

center bottle. |

|

|

|

15th

December 2012 - Machined up 3 PVC rings

that would hold the captive caps. We glued

these with epoxy to the PVC tubes. We also

obtained the bottle caps from the local

supermarket. We got these from hand wash

detergent pump packs. Now we have at least a

6 month supply of hand washing detergent.

The pumps in the caps were cut out and the

hole in the cap enlarged on the lathe so it

would fit on the PVC tube.

Parts cut out for the lighter

manifold |

Test fitting the whole thing

together |

|

|

18th

December 2012 - Finished making 7 new

90mm spliced pairs with the narrow sleeve.

We had used up most of our spare spliced

pairs last year for the commercial and so we

had to make a few for this rocket. We want

to use 3 - 4 spliced pairs per segment on

this rocket.

7 new spliced-pairs |

|

|

|

28th

December 2012 - We glued the whole of

manifold together today using PVC cement.

Partially glued together |

|

|

|

1st January

2013 - Pressure testing the manifold. We

tried pressure testing the manifold today

but have had several problems with getting

good seals. We would fix one leak, but when

pressurised to a higher pressure another

would leak. We decided that this was going

to be too unreliable especially if we were

going to pull the manifold off to fill the

rocket on the pad. So it was decided to

switch to plan B and go with the o-rings.

Ready for first pressure test -

had some leaks |

Test fit of what the Inverter

rocket will look like |

|

|

7th January

2013 - Machined up 2 of the three o-ring

sleeves that will fit into the end of the

manifold. Each sleeve is made of aluminium

and weighs 2 grams. These will be glued into

the ends of the tubes with epoxy. The hole

in the sleeve is 16mm for maximum airflow.

The wall thickness is around 0.75mm.

Stock aluminium |

Sleeves machined to fit |

..with o-rings |

Test fitting rings into the

manifold |

8th January

2013 - Machined up the third o-ring

sleeve. We glued all the the o-ring sleeves into

the manifold with

epoxy.

All 3 sleeves glued in |

Close up of the sleeve in place. |

|

|

12th January

2013 - We pressure tested the air

manifold to 120psi today. There were no

leaks and the manifold was easy to put on

and take off again.

Pressurised to 120psi - no leaks |

|

|

|

15th January

2013 - Gathered up all the tornado

tubes, nozzle, guide rail lugs necessary for

the rocket. We are using 22mm tornado tubes

on the central segment since it is going to

be passing water through them. These should

be hopefully big enough not to choke the

flow too much since the nozzle is only 16mm.

The cross sectional area of the tornado

tubes is roughly double that of the nozzle.

We decided to make up three more spliced

pairs of bottles for this rocket so we

prepared the bottles for those as well.

Fairings, tornado tubes with

seals, nozzle and guide rail

buttons. |

|

|

|

16th January

2013 - Spliced the the 3 new

spliced-pairs

with Sikaflex today. Only 10 more days to

launch so we need to hurry up so the glue

has enough time to fully cure. Prepared the

sleeves for these as well.

17th January

2013 - Finished gluing the sleeves on

with PL premium today. We also did some

preliminary simulations to get an idea

of how the rocket is expected to perform. It

looks like it should do around 500 feet at

120psi. It is hard to enter this particular

rocket's parameters accurately into the

simulator, but at least we have a general

idea. It's a little higher than what we are

actually

expecting, especially with a high drag

rocket like this.

19th January

2013 - Cutting out corriflute fins.

We first made a cardboard template to trace

them out evenly on the sheet. There is a

huge Bunnings store that has just opened up

about 10 minutes away from our place.

They now sell the 5mm and 3mm corriflute

sheets, so very easy to get. We also cut out

the fin cans that the fins will be glued to.

The fins are attached to the lowest single

bottles on the air segments. The 2 fins on

each side are at 90 degrees to each other.

Because the rocket needs to be screwed

together, we allow the fin can to rotate so

that once everything has been tightened we

can rotate the fins to the correct position.

These will be then simply taped in place

like we do with all of our fins.

Fins cut out from 5mm corriflute |

Fin cans |

Gluing fins to the fin cans |

|

We cut out the 4 plywood brackets that

will hold the segments together. We test

drilled a couple and tried sandwiching a

tornado tube between them and then secured

it with a cable tie. I think this system

should work. If not then we'll have to think

of something else. One concern that we have

is that the rocket may twist on itself. Well

that's part of the fun of trying to fly this

rocket.

Cutting out struts from a sheet

of plywood |

4 plywood struts. 40mm x 260mm. |

|

|

20th January

2013 - Gluing the second set of fins to

the fin can. When these cure we will add Sikaflex fillets to the fins.

We also arranged the bottles to go on the

rocket as the black tornado couplings are

about 4mm shorter than the commercial ones.

We need to make sure the tornado tubes

remain in line so we can attach the

brackets. Luckily the spliced pairs of

bottles turned out in various lengths (+/-

5mm) , so we picked the longer ones for the

central segment and the shorter ones for the

outer segments. We need to get cracking

before Saturday because we still need to

pressure test all the bottles, and add the

parachute deploy mechanism.

Gluing the second set of fins |

|

|

|

21st January

2013 - The boys helped pressure test the

10 spliced pairs today to 125psi. To much of

John's disappointment none of the bottles

exploded. :) With the pressure tests done,

we can now assemble most of the rocket. We

added the Sikaflex fillets to the fins as

well.

10 spliced-pairs ready for

testing |

Paul helping test the splices |

Sikaflex fillets on the fins |

|

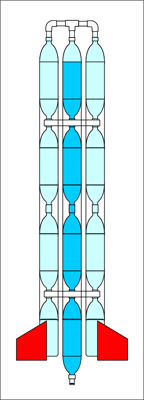

22nd January

2013 - We test assembled the rocket

today so that we could see what it will be

like when set up on the pad ready for

filling with water. We will definitely need

the ladder for this one as well. The rocket

is still missing its parachute deployment

system which is scheduled for tomorrow. We

weighed the rocket as it stands without the

recovery system and it has come in at close

to 1500grams.

While assembling the rocket I noticed

that the bottles were scratched in one

place. This must have been caused by

inserting the bottles into the test

cylinder. We will line it next time to avoid

any further scratches. Hopefully the

scratches aren't enough to weaken the

bottles.

Assembled rocket |

|

|

|

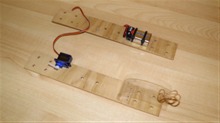

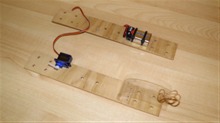

23rd January

2013 - Today we built the deployment

mechanism for the rocket. Because of its

size the rocket is using the larger 800mm

diameter parachute. The deployment mechanism

is very simple and consists of the parachute

being pinned down by a strip of PET plastic

held against one of the plywood struts. A

servo motor is connected to the STII to release

the door. There is no spring to eject the

parachute, it simply just let's it go into

the air stream. The parachute will be

attached to two separate points on the

rocket so it comes down sideways. It will be

interesting to see how much it will swing

side to side on the way down. We have

attached the struts to the tornado tubes

with cable ties.

Struts with deployment mechanism |

The reverse side has the battery |

|

|

24th January

2013 - Finished preparing the rocket,

We added drinking straws to the leading edges of

fins to make them more aerodynamic. KFC

straws are great for this as they fit nicely

in the 5mm Corriflute.

Fin leading edges |

|

|

|

26th January

2013 - Launch day. The full launch

report is available here:

Day 129

Filling with water |

Ready to go |

Maiden flight |

Onboard video frame |

27th January

2013 - We took the rocket completely

apart and discarded the damaged bottles. We

inspected everything for damage and really

the only things that need to be replaced are

the bottles and the parachute. We started

preparing the 6 new bottles for splicing.

Damaged bottles |

Only the bottles are damaged |

|

|

28th January

2013 - We spliced the six bottles with

Sikaflex today and prepared the sleeves that

will go over them. We also re-glued the

retaining ring on the manifold tube with the

24 hour epoxy. This retaining ring holds the

captive cap on the tube and stops the bottle

from flying off. The parachute also got an

inspection, and we will replace it with a

different one for the next flight.

2nd February

2013 - Today we pressure tested the

manifold again to 130psi to make sure it

wasn't damaged during the landing. Luckily

the top bottles acted as a shock absorber so

it's fine. The bottle splices were also

finished today with the sleeve being

attached with PL. We'll wait 4-5 days for

the splices to fully cure before testing

them. I also looked over the deployment

mechanism and realized that the one main

difference between this one and our previous

successful incarnations of it were that they

used the hinge pin method to hold the

parachute in place. This is a much more

secure connection of the door and does not

have the same loading problems. While the

rubber band stretches under load, the hinge

pin doesn't. The hinge pin method will not

work easily in this setup but we'll

implement something more secure.

Re-testing the manifold to

130psi |

Making more splices |

|

|

4th February

2013 - We made some improvements to the

deployment mechanism today. The servo was epoxied to the plywood strut so that it is a

lot more solid. Before it was just wired to

the strut. We also replaced the rubber band

with a loop made of nylon rope. This now

prevents the parachute door from stretching

open under load. Once we assemble the rocket

we will also add a little platform under the

parachute so it can't slide out from under

the door.

Epoxied Servo |

Nylon loop replaces the rubber

band |

|

|

5th February

2013 - We made a new parachute today out

of an old umbrella. The old one was ripped

in too many places. Instead of gluing pieces

of reinforcing fabric and using eyelets we

went with gluing sections of a ribbon for

the shroud lines to attach to. We haven't

used this technique before so we're not

quite sure how well it will work. We just

used regular contact glue.

New parachute |

Detail of the glued ribbon and

shroud line |

|

|

7th February

2013 - We pressure tested the 6 new

spliced pairs and re-assembled the rocket.

We added a little colour to the outside

since the parachute was going to be blue and

yellow and the water was also going to be

blue.

We added a small support platform under

the parachute to stop it from sliding down

during acceleration. This was just a piece

of PET bottle taped to the side of the

bottle.

Arrow shows the support platform |

Parachute held down by door |

...and rests against the

platform |

Assembled rocket ready to fly |

10th

February 2013 - Launch day. This time we

had a much better success. Full launch

report is here:

Day 130.

Blue food colouring |

|

Apogee deployment |

Gentle landing |

30th March

2013 - Launch day - Painting the sky.

This time we put differently coloured water

in each of the spliced pairs in order to

change the water stream colour mid flight.

See the full launch

report from day 132 for more details.

Multi-coloured |

Flight 1 |

Flight 2 |

Air-pulse during flight 1 |

|